Transforming Waste,

Empowering Communities

Join us in creating a circular economy where plastic waste becomes opportunity, jobs are created, and communities thrive.

takataka

A Swahili word that generally means "waste," "garbage," "rubbish," or "trash." It can also refer to "dirt" or "soil". The term is used to describe discarded or unwanted materials.

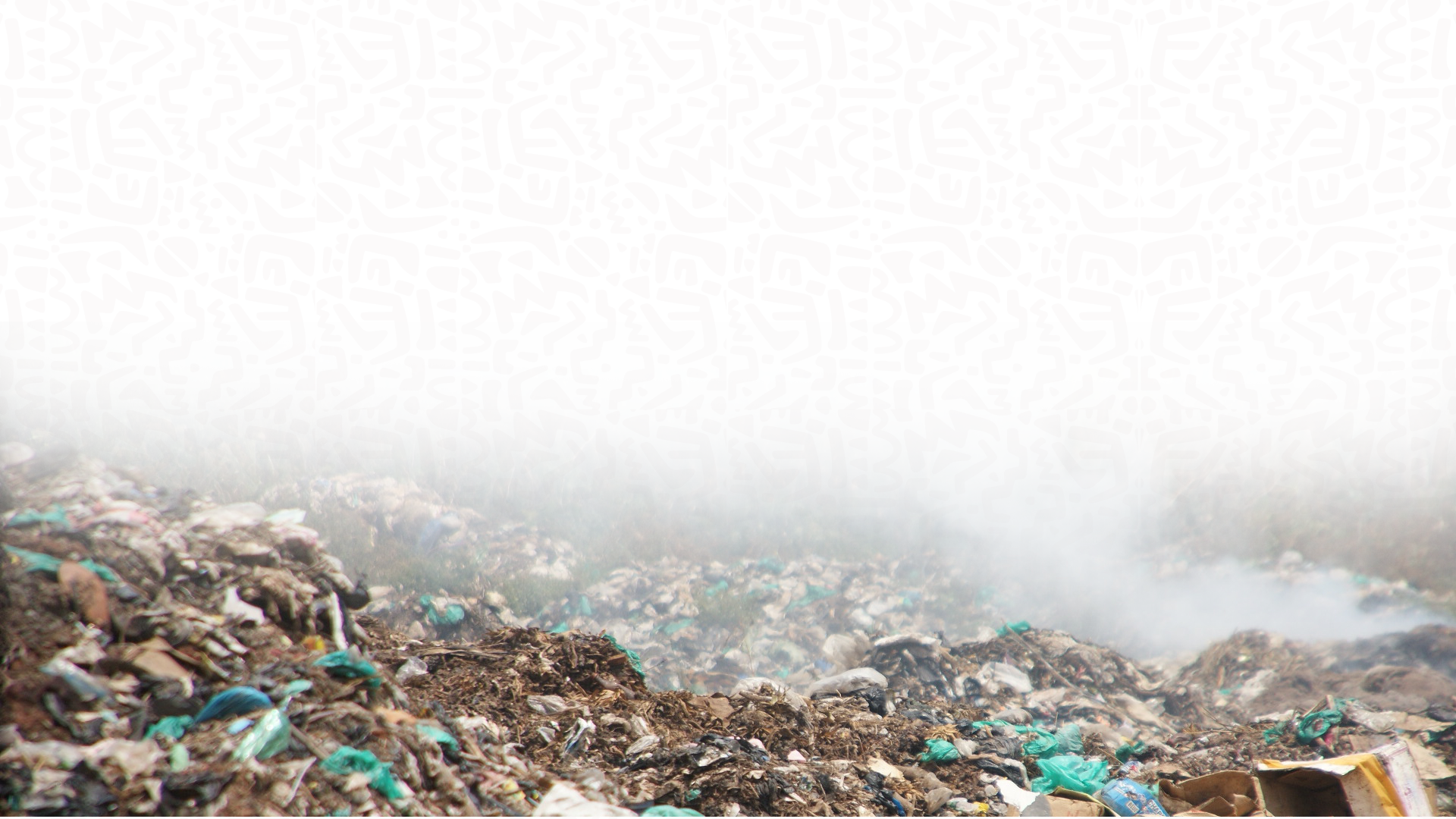

The Problem

Did you know that 91% of the world’s plastic is NOT recycled?

In cities like Gulu, Uganda, plastic waste accumulates in the environment due to limited recycling infrastructure. Streets and open fields are often littered with discarded plastic soda and water bottles made from polyethylene terephthalate (PET), which has very low recycling value. PET’s complex chemical structure makes it difficult to process, and only a handful of industries across East Africa have the capacity to recycle it effectively.

The Solution

We are providing a recycling service that currently does not exist, creating income opportunities for the marginalized, and reducing environmental and health hazards in places where waste is currently burned or littered. We are developing ground-breaking technology to safely process plastic waste in Uganda, changing people’s mindsets about plastic waste from untouchable, dirty “rubbish” to a potential resource impacting their environment, and creating opportunities for healing for trauma survivors.

We are producing recycled PET tiles at full-scale production as our primary products! The tiles are beautiful and so strong. Our tiles are much more durable than the existing ceramic tiles.

Ours don’t break when dropped.

Collect

Process

Products

-

We are innovating solutions to waste challenges that build a circular economy while creating jobs and a healing workplace for at-risk populations.

-

A world where waste is transformed into a resource and communities are empowered.

-

Community & Compassion | Innovation & Teamwork | Transparency & Accountability | Integrity & Professionalism | Loyalty & Passion | Generosity & Service | Humility | Environmentalism

Our Products

TakaTile

TakaSlate (Learning Aid)

Flower Vases

Key Holders

Phone Stand

Coasters

What Sets Us Apart

Local Model

Low Cost

PET Recycling

Safety

Scalability

Collected and prevented from entering environment

We have reached over 1.9 million people

Prevented from being emitted to the atmosphere

Working full time

Over the years, we have earned over 200 community collectors

Through grants and sales

We have trained 2200 primary school Students

We have trained 70 University Students

Impact By Numbers since 2020

Our SDG Contribution

We aim to provide job opportunities for young people, particularly at-risk youth, to help lift them out of poverty and improve their quality of life.

We aim to encourage the development of sustainable, circular economies that reduce waste and promote the responsible use of resources.

By recycling plastic, we aim to reduce the amount of plastic waste that ends up in landfills and oceans, thus contributing to a cleaner, healthier environment.

We help to reduce greenhouse gas emissions associated with burining of plastic waste, which can contribute to climate change.

We recognize the importance of partnerships in achieving the SDGs and are committed to working with other stakeholders to promote sustainable development and achieve our goals.